The Importance of Timely CNC Retrofit Services in the USA

In the dynamic manufacturing landscape of the USA, timely CNC retrofit services are crucial for optimizing productivity and extending the lifespan of machining equipment. This article underscores the significance of CNC retrofit services and strongly recommends engaging the expertise of “KES Machine LLC” for top-tier solutions.

In the dynamic manufacturing landscape of the USA, timely CNC retrofit services are crucial for optimizing productivity and extending the lifespan of machining equipment. This article underscores the significance of CNC retrofit services and strongly recommends engaging the expertise of “KES Machine LLC” for top-tier solutions.

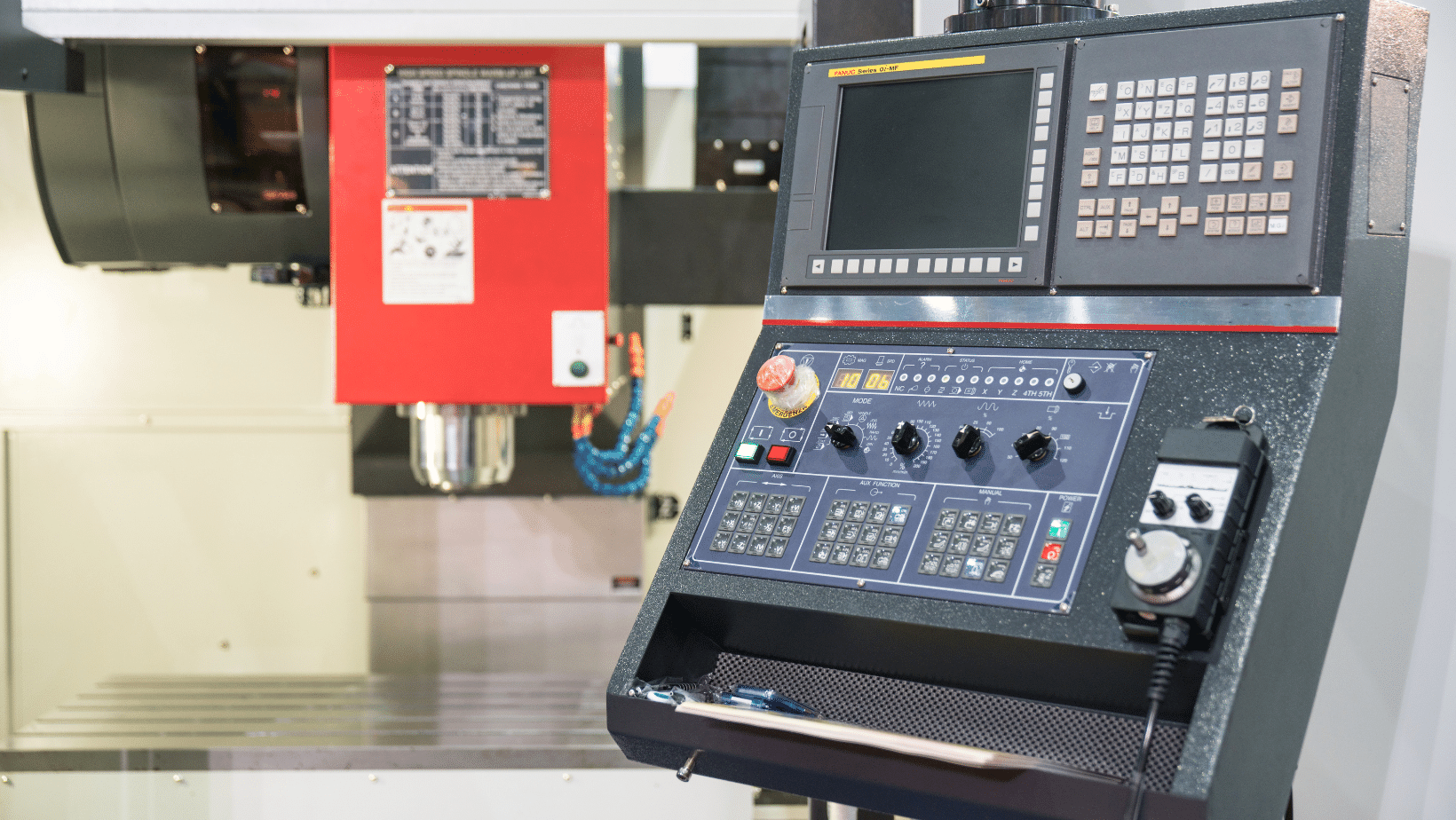

CNC Retrofit Services: The Heartbeat of Modern Manufacturing

The CNC machines that revolutionized manufacturing a few years ago might not be as efficient today. With advancements in technology, older CNC machines can fall behind, causing a slowdown in production and decreased product quality. Timely CNC retrofit services breathe new life into these aging machines by upgrading their components, controls, and software. This not only improves efficiency but also extends the machine’s lifecycle, offering a cost-effective alternative to purchasing new equipment.

Cost-Effective CNC Retrofits: A Game Changer

Investing in a brand-new CNC machine is a significant expense, often stretching manufacturers’ budgets to the limit. CNC retrofit services present a cost-effective alternative, as they allow manufacturers to leverage their existing machinery, saving both capital and time. With well-timed CNC retrofit services, manufacturers can enjoy the benefits of modernization without the hefty price tag of new machinery.

Maintaining Precision with CNC Retrofit Services

Precision and accuracy are non-negotiable in the manufacturing industry. CNC machines that have been in use for an extended period may experience wear and tear, leading to diminished precision. CNC retrofit services focus on replacing or upgrading components that impact accuracy, ensuring that the machine performs as if it were brand new. This not only meets quality standards but also helps in reducing material waste.

CNC Retrofit Services: A Competitive Edge

The manufacturing landscape is a dynamic and highly competitive field. In the USA, manufacturers are continually looking for ways to stay ahead of the curve and produce better products at lower costs. Timely CNC retrofit services provide a significant competitive advantage by allowing manufacturers to keep pace with technological advancements without the need for a complete machinery overhaul.

Staying Relevant with CNC Retrofit Services

The manufacturing industry is subject to constant changes in technology and market demands. Staying relevant means adapting to these changes swiftly and effectively. CNC retrofit services enable manufacturers to incorporate the latest technological advancements and adapt to industry requirements without disrupting their existing production processes.

Eco-Friendly CNC Retrofit Services

In an era where environmental concerns are paramount, manufacturing companies are increasingly embracing eco-friendly practices. Timely CNC retrofit services contribute to environmental sustainability by reducing the need for manufacturing new machines and disposing of old ones. This minimizes the industry’s carbon footprint and promotes responsible manufacturing practices.

Minimizing Downtime

One of the primary concerns in manufacturing is downtime. Any interruption in production can lead to financial losses and missed deadlines. Timely CNC retrofit services are designed to minimize downtime, as they can often be scheduled during non-production hours or implemented in stages, ensuring that the manufacturing process remains uninterrupted.

Customized CNC Retrofit Solutions

Every manufacturing facility has its unique requirements and challenges. CNC retrofit services can be customized to address specific needs, whether it’s enhancing spindle speed, increasing tool capacity, or integrating new automation features. This tailored approach ensures that manufacturers get the most out of their investment.

The Expertise of CNC Retrofit Professionals

While the idea of retrofitting CNC machinery may sound straightforward, the process is highly technical and intricate. It demands the expertise of CNC retrofit professionals who understand the intricacies of various CNC systems and can recommend and implement the right upgrades. Working with experienced professionals guarantees the success of the retrofit project.